From the EPA (April 17, 2012 – Final Ruling) – The estimated revenues from selling the gas that currently goes to waste are expected to offset the costs of compliance, while significantly reducing pollution from this expanding industry. EPA’s analysis of the rules shows a cost savings of $11 to $19 million when the rules are fully implemented in 2015.

Source: http://www.epa.gov/airquality/oilandgas/actions.html

OVERVIEW OF FINAL AMENDMENTS TO AIR REGULATIONS FOR THE OIL AND NATURAL GAS INDUSTRY

FACT SHEET

OVERVIEW OF ACTION

On April 17, 2012, the U.S. Environmental Protection Agency (EPA) issued cost-effective regulations to reduce harmful air pollution from the oil and natural gas industry while allowing continued, responsible growth in U.S. oil and natural gas production.

The final rules include the first federal air standards for natural gas wells that are hydraulically fractured, along with requirements for several other sources of pollution in the oil and gas industry that currently are not regulated at the federal level. The rules for fractured gas wells rely on proven, cost-effective technology and practices that industry leaders are using today at about half of the fractured natural gas wells in the U.S.

EPA extensively sought comment on the proposed rules, which the agency was required to review under the Clean Air Act. Today’s final action includes a number of changes made in response to those comments. The final rules provide flexibility for industry to ensure equipment is available to capture natural gas in time to meet compliance deadlines, while maintaining the environmental benefits from the proposal. The rules also include incentives for industry to modernize equipment and reduce pollution early, and changes to reporting requirements to strengthen accountability.

A key component of the final rules is expected to yield a nearly 95 percent reduction in VOCs emitted from more than 11,000 new hydraulically fractured gas wells each year. This significant reduction would be accomplished primarily through the use of a proven process – known as a “reduced emissions completion” or “green completion” — to capture natural gas that currently escapes to the air.

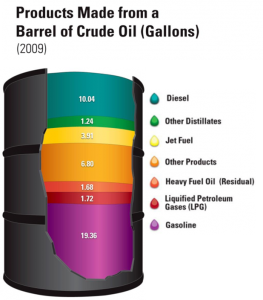

In a green completion, special equipment separates gas and liquid hydrocarbons from the flowback that comes from the well as it is being prepared for production. The gas and hydrocarbons can then be treated and used or sold, avoiding the waste of natural resources that cannot be renewed.

The estimated revenues from selling the gas that currently goes to waste are expected to offset the costs of compliance, while significantly reducing pollution from this expanding industry. EPA’s analysis of the rules shows a cost savings of $11 to $19 million when the rules are fully implemented in 2015.

Some states, such as Wyoming and Colorado, require green completions, as do some cities,

including Fort Worth and Southlake, Texas. In addition, data provided to EPA’s Natural Gas STAR program show that a number of companies are using green completions voluntarily. Today’s rule builds on the emission reductions these leaders have taken, leveling the playing field across the industry and ensuring this smart environmental and business practice is used in all states where gas wells are fractured.

POLLUTION REDUCTION, CONTINUED NATURAL GAS PRODUCTION

The VOC emission reductions from wells, combined with reductions from storage tanks and other equipment, are expected to help reduce ground-level ozone in areas where oil and gas production occurs. In addition, the reductions would yield a significant environmental co-benefit by reducing methane emissions from new and modified wells. Methane, the primary constituent of natural gas, is a potent greenhouse gas – more than 20 times as potent as carbon dioxide when emitted directly to the atmosphere. Oil and natural gas production and processing accounts for nearly 40 percent of all U.S. methane emissions, making the industry the nation’s single largest methane source.

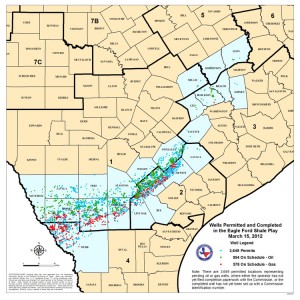

Corpus Christi – According to a Corpus Christi Caller Times report and the Texas Department of Transportation, funds are not avaialble to fix the crumbling roads. Some responsible oil companies are stepping up (Thank You Pioneer Natural Resources and Petrohawk Energy Corp.)

Corpus Christi – According to a Corpus Christi Caller Times report and the Texas Department of Transportation, funds are not avaialble to fix the crumbling roads. Some responsible oil companies are stepping up (Thank You Pioneer Natural Resources and Petrohawk Energy Corp.)